FlowMark Disinfection System Treatment

The objective in water treatment for cooling towers, chillers, heat exchangers and evaporative condensers is to protect the equipment from corrosion, control bacteria growth, eliminate scale on heat transfer surfaces and piping, prevent biofilm, control algae growth and control the accumulation of dirt and debris in the system.

Over the years, almost every component of these systems have evolved – cooling towers, chillers, heat exchangers, evaporative condensers, pumps, drives – all have become more energy and water efficient. And yet in the face of such technological advances, the single most important process associated with the longevity and efficient operation of water-cooled systems – water treatment – has remained mired in the hazardous chemicals of the past — until now.

The FlowMark Disinfection Systems Water Treatment System

The FlowMark System works by generating a powerful disinfecting gas and introducing it into the cooling tower water through submerged diffusers installed in the cooling tower basin. The process is recognized by the EPA as “Advanced Oxidation Process”. The FlowMark Water Systems technology:

- Produces Highly Reactive Hydroxyl Radicals

- Low ozone (O3) production (<0.5 PPM)

- Creates Measureable Hydrogen Peroxide

- Controls Bacteria

- Installs in conductivity control loop

- No air pump required

- No diffusers required

Water Treatment Solutions

Cooling Towers, Chillers, Heat Exchangers & Evaporative Condensers

Conservation Solutions’ Water Treatment Division operates with the slogan “Expect Superior Water Treatment”, and that phrase represents our sole objective in serving our customers. With the FlowMark Disinfection Systems Technology as the centerpiece of our water treatment products and services, we are literally changing the way that facilities view water treatment. In some cases we team with our partners to address specific water conditions with non-hazardous chemicals to ensure protection of the cooling system equipment. In most cases, the FlowMark Water Systems technology handles all the water treatment requirements without chemicals.

Hard Water? – Reduced Water Flow & Lost Energy

Applications:

- Chillers

- Cooling Towers, Evaporative Condenser

- Domestic Hot Water Heaters

- Heat Exchangers

- Process Applications

- Eliminate or Reduce the On-Going Cost of Water Softeners

The FlowMark Water Treatment Disinfection System is classified as an Advanced Oxidation Process. Oxygen is split into singlet oxygen atoms as it passes through a lamp chamber containing a specific wavelength UV lamp. The oxidizing gas is introduced to the cooling tower water via Venturi injection into the conductivity control loop. The singlet oxygen atoms interact with water molecules forming hydroxyl and oxygen radicals which trigger various chemical reactions, oxidizing contaminants including minerals and bacteria. In addition, some oxygen radicals join with water molecules (H2O) to form a measureable residual of Hydrogen Peroxide (H2O2), a trusted long lasting, nontoxic biocide.

Recent News

Water Use – Are Your Water Costs Out of Control?

Conservation Solutions is highly effective in designing water efficiency programs tailored to meet your budget. We take a comprehensive look at opportunities to reduce water use by increasing efficiency. We work closely with customers to dramatically reduce water use in buildings by identifying and installing state of the art technologies that best meet the unique needs of your building or facility.

Water Resources: Why Water Conservation & Water Efficiency is Important

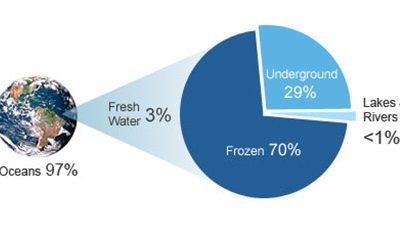

Le Monde diplomatique: Water stress is defined as having a high percentage of water withdrawal compared to total available water in the area Water: Only 3% of water on earth is fresh water. 70% of the fresh water is lockedup in ice caps and glaciers. Only 1% of the...

Solving the scale problems associated with Landfills & Wastewater

Landfill Leachate Collection Systems (LCS) can often suffer from excessive scaling and clogging of piping systems, pumps, etc. Conventional remediation methods include expensive hydro-blasting and/or acid cleaning but the problem quickly returns. Problems with scale...