FAQ

Questions About Venturi Nozzle Steam Traps

How do they handle modulating loads?

Venturi Nozzle traps work excellent on modulating loads. They are sized for the maximum design load – valve full open. As the valve pinches down – due to less demand – steam pressure drops. Less steam will pass into the coil but the coil surface area does not change. The steam will then condense at a greater rate than it is replaced. The steam takes up more volume at a lower pressure. This pressure drop will allow the Venturi Nozzle Steam trap to function at a higher rate of efficiency. If the valve closes all the way the steam will condense and a vacuum will form. The coils vacuum breaker will allow air in and condensate will flow by gravity.

Do they always blow steam because they are always open?

Each Venturi Nozzle Steam trap is designed to completely remove condensate at every trap station. There is a minor bleed of steam. This bleed is so small that it is less than the bleed of a properly functioning mechanical trap.

Don’t they clog up all the time?

Typically no. But if a steam system is considered “dirty” it may be a legitimate concern in the lower areas of the system – (drip legs). The best case would be to clean the system by removing built up sediment in the mud-legs during installation. This would remove the problem of dirt and solve a customer’s problem.

If this cannot be done due to access, or other reasons we would recommend the best mechanical trap available. Radiators inserts are safe from fouling due to their locations higher in the system and Heat Exchanger, Domestic Hot Water, Air Handler traps are not susceptible due to their larger orifice size. All Venturi Nozzle Steam traps come with screens to protect the traps from debris.

How do they vent air and handle start-ups?

Physics tells us that air is heavier than steam under the same temperature and pressure.

During start-up the heavier air passes through the Venturi Nozzle Steam traps which are located at low points in the system. This provides a more controlled warm up of steam mains.

Are they Difficult to maintain?

Venturi Nozzle Steam traps are actually easier to maintain. A Venturi Nozzle Steam trap cannot fail open. This eliminates the need to test all traps every year and change out the 5 to 10 percent that typically fail (ASHRAE) or change all the traps every 3 to 5 year as recommended by most mechanical trap manufacturers. If a trap fails closed it simply needs to be cleaned and put back in service.

Maintenance should be blowing down strainers in the distribution system a couple times a year to keep the system clean. That should be done with mechanical traps as well to keep the clean from debris which can cause them to fail open.

Questions About SteamLoc® Orifice Traps

How do they handle modulating loads?

SteamLoc® Orifice traps work excellent on modulating loads. They are sized for the maximum design load – valve full open. As the valve pinches down – due to less demand – steam pressure drops. Less steam will pass into the coil but the coil surface area does not change. The steam will then condense at a greater rate than it is replaced. The steam takes up more volume at a lower pressure. This pressure drop will allow the SteamLoc® trap to function at a higher rate of efficiency. If the valve closes all the way the steam will condense and a vacuum will form. The coils vacuum breaker will allow air in and condensate will flow by gravity.

Do they always blow steam because they are always open?

Each SteamLoc® trap is designed to completely remove condensate at every trap station. There is a minor bleed of steam. This bleed is so small that it is less than the bleed of a properly functioning mechanical trap.

Don’t they clog up all the time?

Typically no. But if a steam system is considered “dirty” it may be a legitimate concern in the lower areas of the system – (drip legs). The best case would be to clean the system by removing built up sediment in the mud-legs during installation. This would remove the problem of dirt and solve a customer’s problem.

If this cannot be done due to access or other reasons we would recommend the best mechanical trap available. Radiators inserts are safe from fouling due to their locations higher in the system and Heat Exchanger, Domestic Hot Water, Air Handler traps are not susceptible due to their larger orifice size. All SteamLoc® traps come with screens to protect the traps from debris.

How do they vent air and handle start-ups?

Physics tells us that air is heavier than steam under the same temperature and pressure.

During start-up the heavier air passes through the SteamLoc® traps which are located at low points in the system. This provides a more controlled warm up of steam mains.

Are they Difficult to maintain?

There are actually easier to maintain. A SteamLoc® trap cannot fail open. This eliminates the need to test all traps every year and change out the 5 to 10 percent that typically fail (ASHRAE) or change all the traps every 3 to 5 year as recommended by most mechanical trap manufacturers. If a trap fails closed it simply needs to be cleaned and put back in service.

Maintenance should be blowing down strainers in the distribution system a couple times a year to keep the system clean. That should be done with mechanical traps as well to keep the clean from debris which can cause them to fail open. Check out our SteamLoc® page here.

How can you save on water, energy and chemical costs?

Calcite Scale

- Problems with Calcite Scale in any of these applications?

- heat exchangers

- Chillers

- Hot water heaters

- Fluid coolers

- Evaporative condensers

- Swamp coolers

- Ice machines

- Misting systems

- steam boilers,

- process equipment?

- Wasting time chiseling out calcite scale?

- Complaints about not enough hot water?

- Pressure to reduce salt use with Water Softener?

- High energy bills

Cooling Towers

- Are you trying to reduce hazardous chemicals in your Building or on your campus?

- Are you concerned about hazardous chemicals’ impact on staff and contractors and associated liability?

- Legionella concerns?

- Problems with Algae in the cooling tower

- Problems with debris building up in your towers and chillers

- High energy costs associated with cooling

- High water use associated with filtration backwash

Air Quality Issues

AIR – How Do You Know You Are Maintaining Optimal Air Quality and Save Energy In Your Building Or Facility?

AIR – How Do You Know You Are Maintaining Optimal Air Quality and Save Energy In Your Building Or Facility?

Hospitals & Healthcare Facilities

- Who is tracking Hospital Acquired Infections (HAIs)?

- What about Ventilator Associated Pneumonia?

- What is the liability associated with HAIs?

- Is hospital staff absenteeism an issue because of poor Indoor Air Quality (IAQ)?

- Is hospital staff performance affected by poor IAQ?

Office Buildings, Multifamily Housing

- Are you getting complaints about poor IAQ?

- Complaints about Odors?

- Complaints about Allergies or sick building syndrome?

- Is the performance of the staff and building occupants affected by poor IAQ? Is it costing you money?

- Are building occupant absenteeism related to poor IAQ?

- Is periodic cleaning of air handler (AHU) coils enough to keep up with the rate Bacteria, Mold and Viruses grow on the coils even with HEPA filters?

- Who is tracking Bacteria, Mold and Viruses building up on AHU coils?

- How much energy is being wasted when biofilm accumulates in the cooling systems coils

Food Processing and Shopping Centers

- What about protecting food from pathogens?

- How can you increase profits by extending the shelf life of produce?

Recent News

Water Use – Are Your Water Costs Out of Control?

Conservation Solutions is highly effective in designing water efficiency programs tailored to meet your budget. We take a comprehensive look at opportunities to reduce water use by increasing efficiency. We work closely with customers to dramatically reduce water use in buildings by identifying and installing state of the art technologies that best meet the unique needs of your building or facility.

Water Resources: Why Water Conservation & Water Efficiency is Important

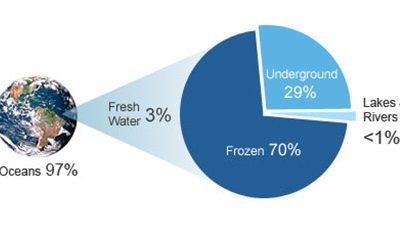

Le Monde diplomatique: Water stress is defined as having a high percentage of water withdrawal compared to total available water in the area Water: Only 3% of water on earth is fresh water. 70% of the fresh water is lockedup in ice caps and glaciers. Only 1% of the...

Solving the scale problems associated with Landfills & Wastewater

Landfill Leachate Collection Systems (LCS) can often suffer from excessive scaling and clogging of piping systems, pumps, etc. Conventional remediation methods include expensive hydro-blasting and/or acid cleaning but the problem quickly returns. Problems with scale...